CZS supported AI projects – session 1

10:30 AM – 11:40 PM

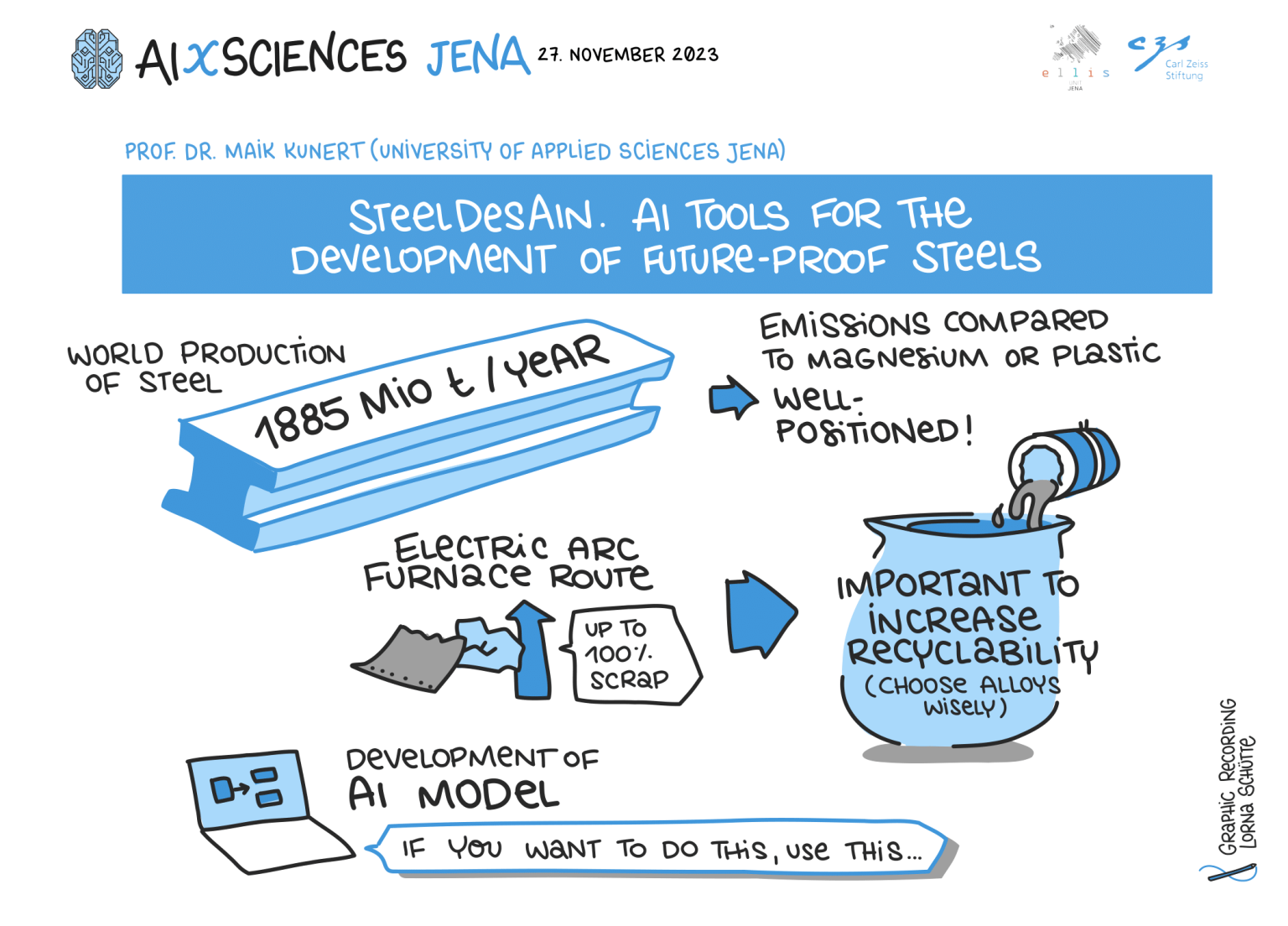

SteelDesAIn. AI tools for the development of future-proof steels

The presentation will address the topic of the application of Artificial Intelligence (AI) in steel manufacturing and development. It starts by highlighting the importance of steel in our modern world, referring to its wide range of applications and its crucial role in infrastructure. At the same time, the current challenges in the steel industry are highlighted: on the one hand, CO2 emissions must be significantly reduced, and on the other hand, the supply of high-quality steel must also be ensured in the future. Alloying elements that are becoming scarcer and rapidly changing amework conditions pose additional challenges for the steel industry. The main part of the presentation will explain how AI technologies can be used to address these challenges. Here, it will be emphasised that machine learning and advanced data analysis make it possible to optimise steel development and production processes.

Speaker and Project leader

Maik Kunert dedicated his efforts to the Max-Planck-Institute for Metal Research in Stuttgart, completing his Ph.D. in 2000 on „Mechanical Properties on Nanometer Scale and their Relations to Composition and Microstructure.“ From 2000 to 2002, Maik Kunsert served as an assistant in teaching and research at the Institute for Metal Science at the University of Stuttgart. Between 2002 and 2005, he held leadership roles as the Head of the Testing Center and Research Project Leader at the Research Association for Tools and Materials e.V. From 2005 to 2006 he contributed his expertise as a System Expert in Quality Management at Infineon Technologies Dresden GmbH & Co. OHG. Since September 2006, he has been a Professor of Material Engineering and Biomaterials at the Ernst-Abbe University of Applied Sciences in Jena. In this capacity, he continues to make contributions to academic research and teaching in the field of materials.

Steel manufacturers are currently facing major challenges: On the one hand, CO2 emissions must be significantly reduced, on the other hand, the supply of high-quality steel for e.g. wind turbines and the construction industry must also be ensured in the future. Alloying elements that are becoming scarcer and rapidly changing framework conditions pose additional challenges for the steel industry. In order to make the steel production process more effective, the team at the EAH Jena is using artificial intelligence methods to develop a SteelDesigner, which will calculate an optimal composition of steels in advance of production to achieve certain properties, such as strength. In addition to properties, costs and composition, previously neglected aspects such as security of supply, recyclability and ecological and social impacts during the life cycle are to be included in the material development. In addition, MicroGrapher is being developed to analyse existing steel alloys. Based on microstructural images and process parameters, such as information on temperature and the degree of forming, it determines microstructural parameters that are essential for the application behaviour of the steels. The project is intended to contribute to the economically and ecologically sound transformation of the domestic steel industry and thus strengthen its competitiveness.

Principal Investigator